| Code |

Description |

MAP |

|

|

|

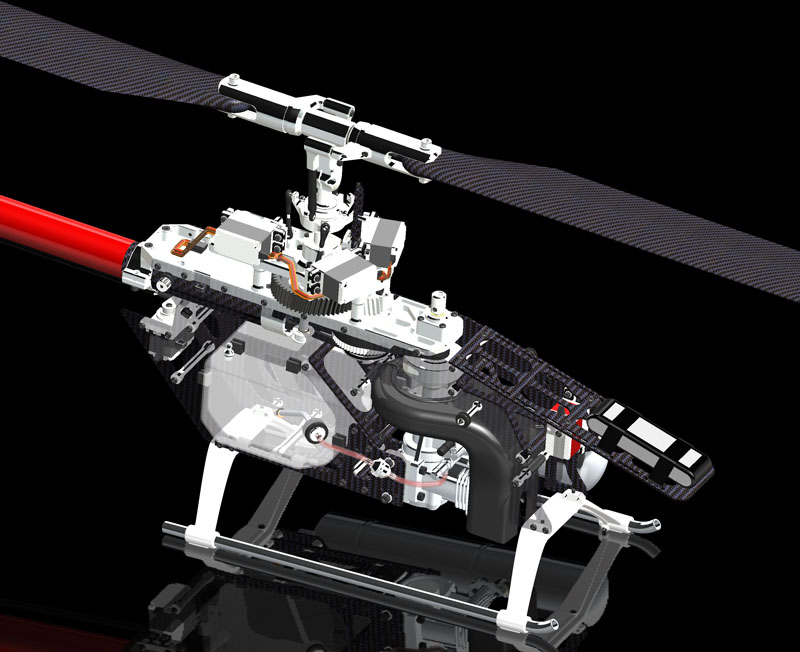

| AV950001 |

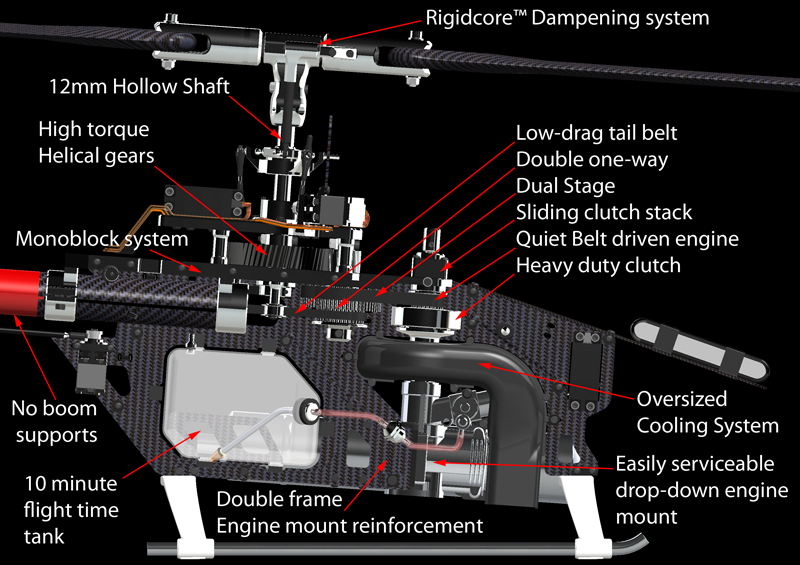

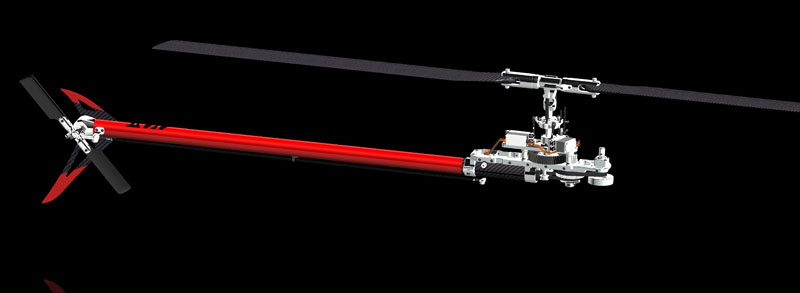

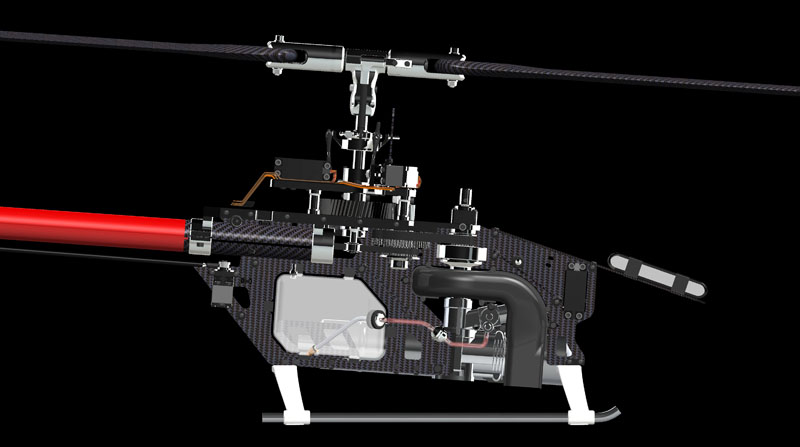

Avant Mostro 700 Electric Radio Control Kit with DFC head |

$ 949.00 |

| AV950002 |

Avant Mostro 700 Electric Radio Control Kit with Follower Arms Head |

$ 949.00 |

|

|

|

| AV960001 |

Avant Mostro 700 Nitro Radio Control Kit with DFC head |

$ 949.00 |

| AV960002 |

Avant Mostro 700 Nitro Radio Control Kit with Follower Arms Head |

$ 949.00 |

|

|

|

| SPARE PARTS |

|

|

| AV950080-Y |

Avant Mostro 700 Electric Painted Fiberglass Canopy Neon Yellow |

$ 100.00 |

| AV950080-R |

Avant Mostro 700 Electric Painted Fiberglass Canopy Red |

$ 100.00 |

| AV960080 |

Avant Mostro 700 Nitro Painted Fiberglass Canopy Red |

$ 100.00 |

| AV950085-Y |

Avant Mostro 700 100% Carbon Tail Boom Neon Yellow |

$ 59.99 |

| AV950085-R |

Avant Mostro 700 100% Carbon Tail Boom Red |

$ 59.99 |

| AV950306-Y |

Avant Mostro Carbon Vertical Fin Neon Yellow |

$ 19.99 |

| AV950306-R |

Avant Mostro Carbon Vertical Fin Red |

$ 19.99 |

|

|

|

|

|

|

| AV950100 |

Avant Mostro 1mm x 10mm ID Shaft Spacer |

$ 4.99 |

| AV950101 |

Avant Mostro 12mm Collar |

$ 9.99 |

| AV950102 |

Avant Mostro Knurled Thumbscrew for Canopy |

$ 7.99 |

| AV950103 |

Avant Mostro Canopy Support Post |

$ 8.99 |

| AV950104 |

Avant Mostro Mounting Mini-Block |

$ 4.99 |

| AV950105 |

Avant Mostro 56mm Rails Spacer (2) |

$ 11.99 |

| AV950106 |

Avant Mostro 60mm Rails Spacer (2) |

$ 11.99 |

| AV950107 |

Avant Mostro Frames Support Spacer |

$ 12.99 |

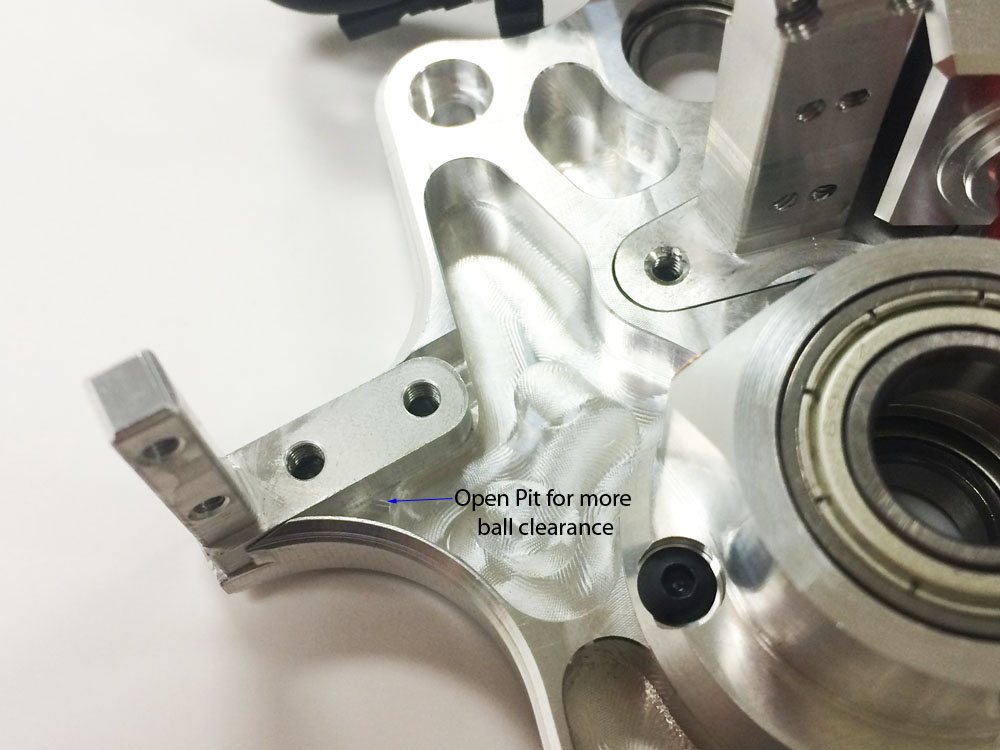

| AV950108 |

Avant Mostro Swashplate Assembly |

$ 48.99 |

| AV950109 |

Avant Mostro Main Shaft |

$ 21.99 |

| AV950110 |

Avant Mostro 10mm Spindle |

$ 11.99 |

| AV950111 |

Avant Mostro Intermediate Shaft |

$ 9.99 |

| AV950112 |

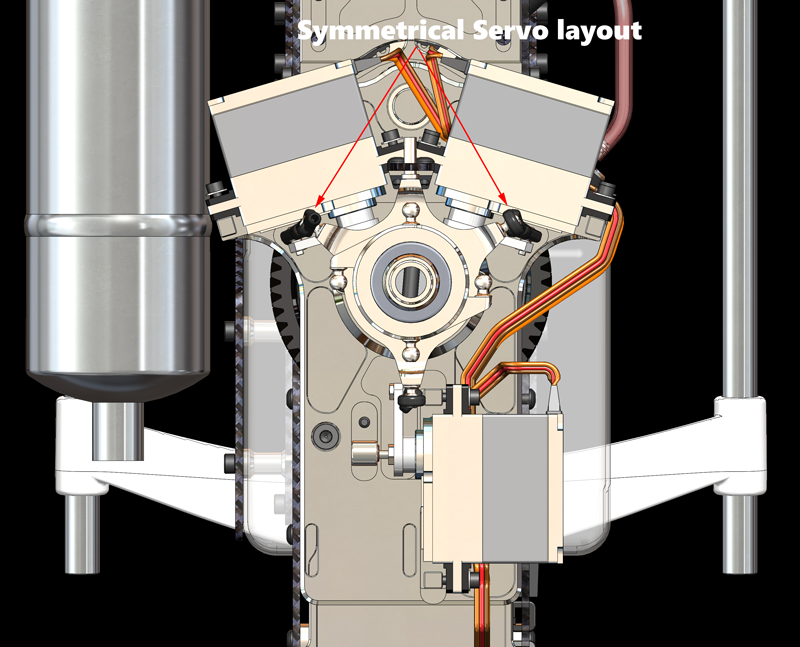

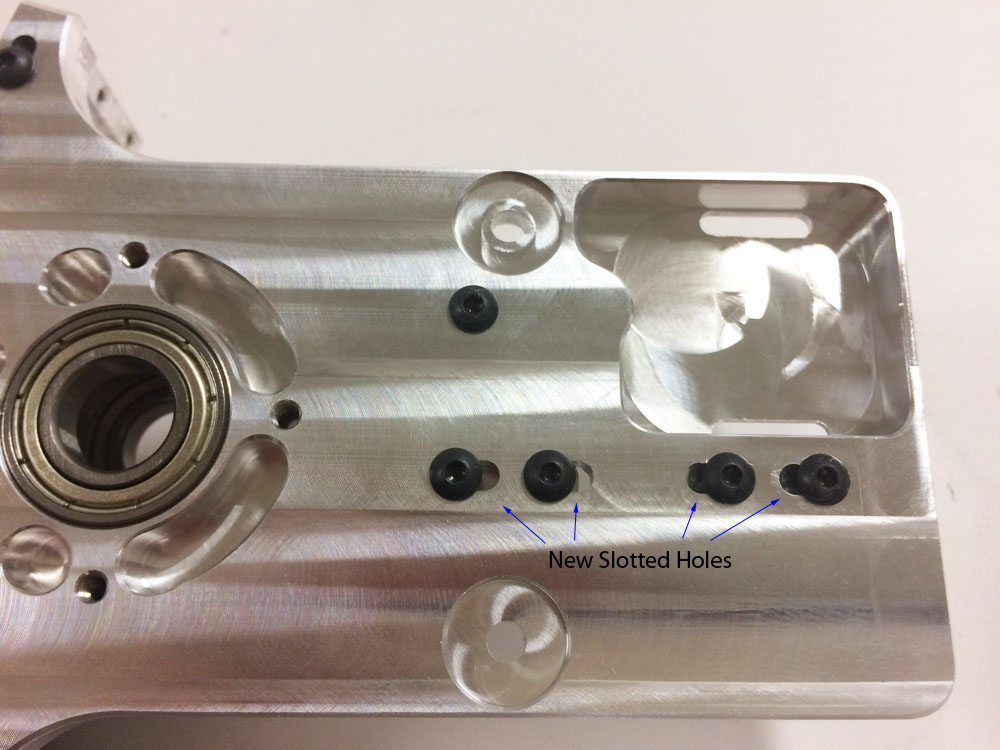

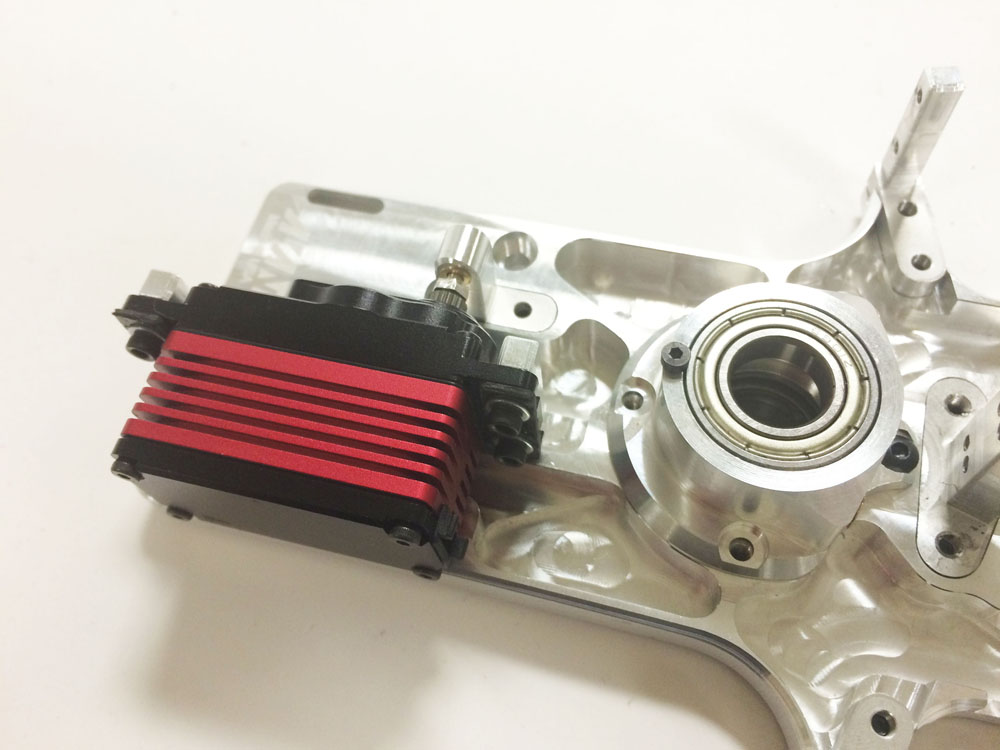

Avant Mostro Top Servo Mounting Plate |

$ 55.99 |

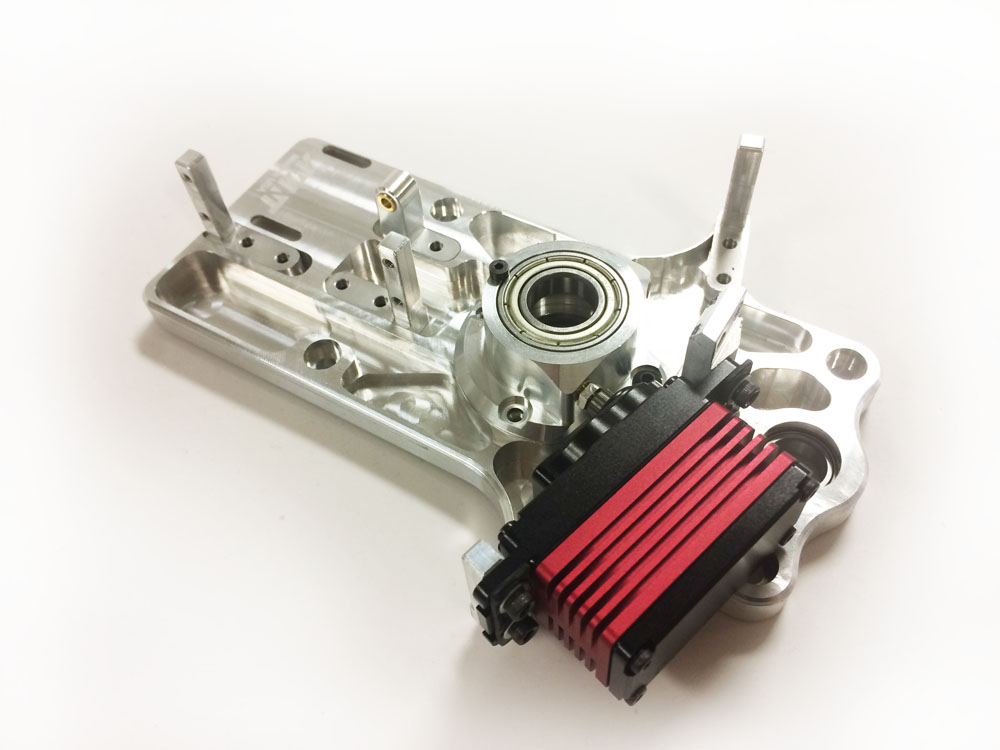

| AV950113 |

Avant Mostro Bottom Gear Mechanics Plate |

$ 59.99 |

| AV950114 |

Avant Mostro Motor Mount Plate |

$ 24.99 |

| AV950115 |

Avant Mostro Gear Mechanics Pillar (2) |

$ 9.99 |

| AV950116 |

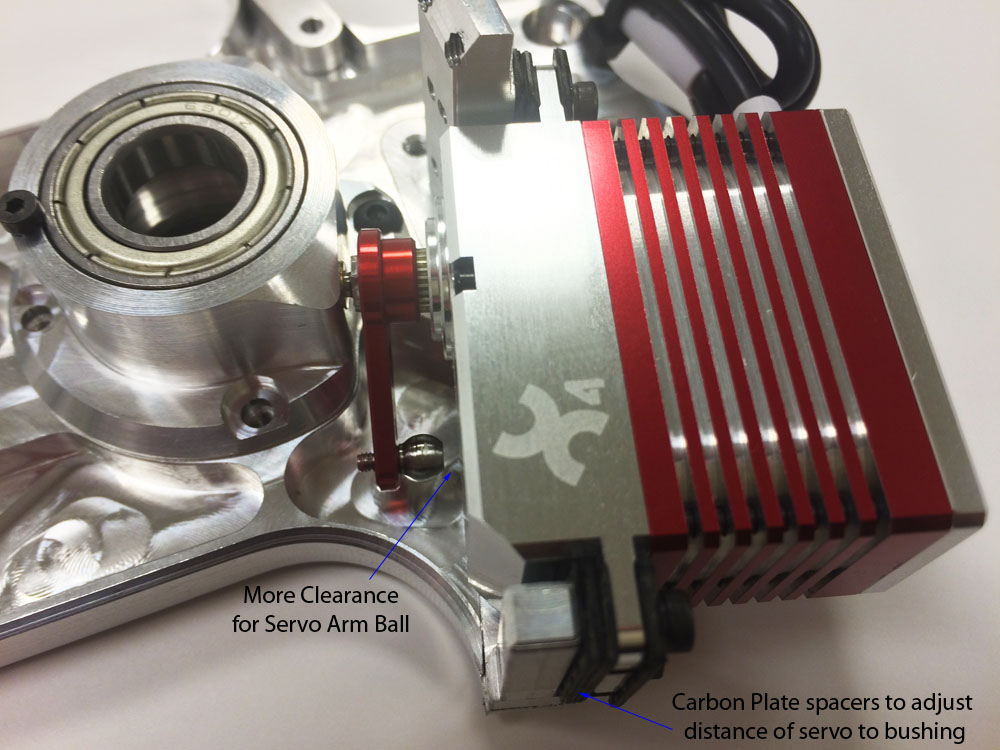

Avant Mostro Servo Side Post |

$ 5.99 |

| AV950117 |

Avant Mostro Back Servo Bushing Post |

$ 6.99 |

| AV950118 |

Avant Mostro CCPM Guide Post |

$ 11.99 |

| AV950119 |

Avant Mostro Top Main Shaft Bearing Block |

$ 21.99 |

| AV950120 |

Avant Mostro Main Gear Hub |

$ 25.99 |

| AV950121 |

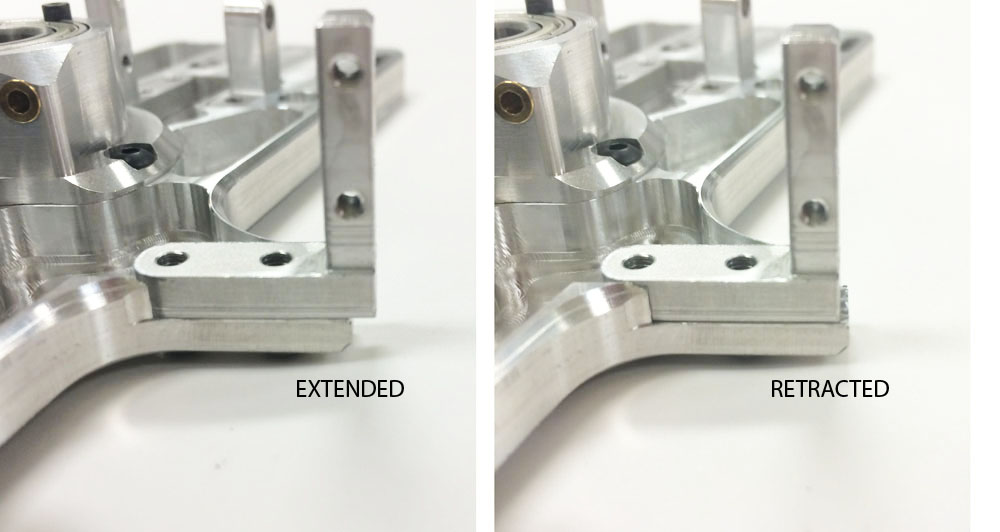

Avant Mostro Landing Gear |

$ 14.99 |

| AV950122 |

Avant Mostro Boom Clamp |

$ 11.99 |

| AV950123 |

Avant Mostro CNC Machined Pushrod Guide Bracket |

$ 9.99 |

| AV950124 |

Avant Mostro Tail Servo Mount |

$ 7.99 |

| AV950125 |

Avant Mostro Tail Fin Support Bracket |

$ 5.99 |

| AV950126 |

Avant Mostro Tensioner Arm Torsion Spring |

$ 7.99 |

| AV950128 |

Avant Mostro Locking Bracket Torsion Spring |

$ 7.99 |

| AV950130 |

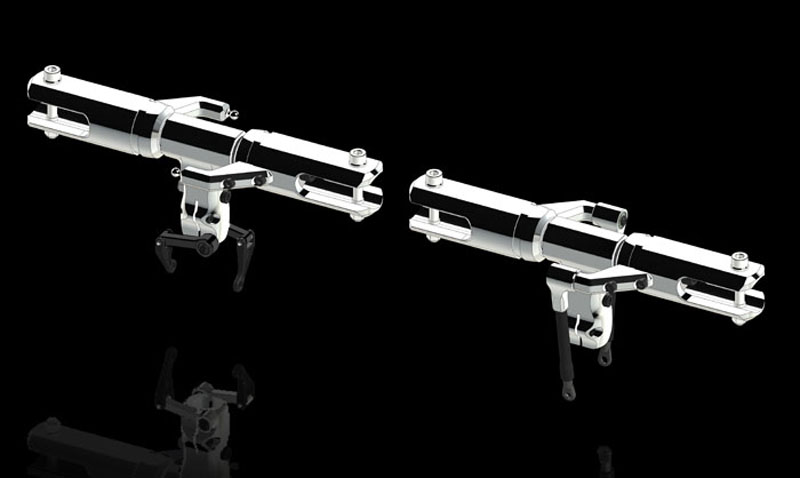

Avant Mostro DFC Yoke |

$ 44.99 |

| AV950131 |

Avant Mostro DFC Pitch Arm (2) |

$ 25.99 |

| AV950132 |

Avant Mostro DFC Pivot with Bearings and Setscrews (2) |

$ 23.99 |

| AV950133 |

Avant Mostro DFC Delrin Links with Threaded Rods and Ball Links (2) |

$ 18.99 |

| AV950134 |

Avant Mostro DFC Axle (1) |

$ 9.99 |

| AV950140 |

Avant Mostro Main Blade Grip Set of two grips |

$ 69.99 |

| AV950141 |

Avant Mostro CNC RigidCore™ Dampener set |

$ 14.99 |

| AV950142 |

Avant Mostro Main Blade Grip M5 Bushings 8mm OD (2) |

$ 11.99 |

| AV950150 |

Avant Mostro FA Yoke |

$ 44.99 |

| AV950151 |

Avant Mostro FA Pitch Arm (2) |

$ 25.99 |

| AV950153 |

Avant Mostro FA Turnbuckle Threaded Rods (2) |

$ 15.99 |

| AV950160 |

Avant Servo Arm Screw with integrated pin M3 (JR) (Qty 3) |

$ 14.99 |

| AV950161 |

Avant Servo Arm Screw with integrated pin M2.5 (FUT) (Qty 3) |

$ 14.99 |

| AV950163 |

Avant 16mm M2.6 Threaded Rods (3) |

$ 5.99 |

| AV950164 |

Avant Air Diverter Plate Bracket Spacer Post (2) |

$ 8.99 |

| AV950165 |

Avant Locking Bracket Spacer Post (2) |

$ 8.99 |

| AV950166 |

Avant 1mm Spacer for M3 Screws (2) |

$ 5.99 |

| AV950180 |

Avant Bladeholder/Caddy for the Mostro 700 |

$ 14.99 |

| AV950181 |

Avant Hook and Loop 30mm wide buckle strap Standard length (2) |

$ 6.99 |

| AV950182 |

Avant Hook and Loop 30mm wide buckle strap Long length (2) |

$ 7.99 |

| AV950183 |

Avant Velcro Sticky Back Tape for Canopy |

$ 4.99 |

| AV950201 |

Avant Mostro 20T Motor Pulley (6mm Shaft Kit default) |

$ 16.99 |

| AV950202 |

Avant Mostro 21T Motor Pulley (6mm Shaft) |

$ 16.99 |

| AV950203 |

Avant Mostro 22T Motor Pulley (6mm Shaft) |

$ 16.99 |

| AV950204 |

Avant Mostro 23T Motor Pulley (6mm Shaft) |

$ 16.99 |

| AV950205 |

Avant Mostro 20T Motor Pulley (8mm Shaft) |

$ 16.99 |

| AV950206 |

Avant Mostro 21T Motor Pulley (8mm Shaft) |

$ 16.99 |

| AV950207 |

Avant Mostro 22T Motor Pulley (8mm Shaft) |

$ 16.99 |

| AV950208 |

Avant Mostro 23T Motor Pulley (8mm Shaft) |

$ 16.99 |

| AV950209 |

Avant Mostro 25T Tail Pulley |

$ 24.99 |

| AV950210 |

Avant Mostro 26T Tail Pulley (Kit default) |

$ 24.99 |

| AV950215 |

Avant Mostro 37T Conical Tail Pulley with plate |

$ 27.99 |

| AV950216 |

Avant Mostro 61T Double One-Way Clutch Pulley |

$ 45.99 |

| AV950217 |

Avant Mostro 58T CNC Machined Helical Main Gear |

$ 34.99 |

| AV950218 |

Avant Mostro 17T Helical pinion |

$ 16.99 |

| AV950219 |

Avant Mostro Idler Pulley with Bearings (1) |

$ 11.99 |

| AV950220 |

Avant Mostro Idler Tensioner Arm with Bearings (1) |

$ 11.99 |

| AV950221 |

Avant Mostro Idler Arm Bearing Post |

$ 7.99 |

| AV950222 |

Avant Electric Mostro 700 Motor Belt |

$ 22.99 |

| AV950223 |

Avant Mostro 700 Tail Belt |

$ 34.99 |

| AV950224 |

Avant Mostro Tail Case with Cap and Bearings |

$ 64.99 |

| AV950225 |

Avant Mostro Metal Tail Blade Grip set of two with counter weight |

$ 27.99 |

| AV950226 |

Avant Mostro Tail Slider assembly |

$ 32.99 |

| AV950227 |

Avant Mostro Tail Pitch L-Lever with Bearings and Liner |

$ 17.99 |

| AV950228 |

Avant Mostro Tail Collar for 6mm Shaft |

$ 6.99 |

| AV950229 |

Avant Mostro Tail Idler Pulley Post |

$ 9.99 |

| AV950230 |

Avant Mostro Tail L Lever Support Bracket |

$ 14.99 |

| AV950300 |

Avant Mostro Electric Carbon Side Frame |

$ 99.98 |

| AV950301 |

Avant Mostro Electric Carbon Battery Sliding Plate |

$ 22.99 |

| AV950302 |

Avant Mostro Carbon Battery Rail Set for one frame |

$ 14.99 |

| AV950303 |

Avant Mostro ESC Carbon Plate |

$ 11.99 |

| AV950304 |

Avant Mostro CCPM guide Carbon Plate |

$ 6.99 |

| AV950305 |

Avant Mostro Air Diverter Carbon Plate |

$ 11.99 |

| AV950307 |

Avant Optional Electronics Mounting Side Plates |

$ 16.99 |

| AV950308 |

Avant Optional bottom ESC mounting plate Kit |

$ 44.99 |

| AV950309 |

Avant Carbon Servo Spacers (10) |

$ 9.99 |

| AV950310 |

Avant Mostro Carbon Pushrod with threaded ends |

$ 14.99 |

| AV950311 |

Avant Mostro Carbon Diverter Plate Bracket (2) |

$ 11.99 |

| AV950312 |

Avant Mostro Carbon Battery Tray Locking Bracket |

$ 14.99 |

| AV950313 |

Avant Mostro Knurled Thumbscrew for Air Diverter Plate |

$ 7.99 |

| AV950314 |

Avant Optional Horizontal Electronics Mounting Plate |

$ 26.99 |

| AV950500 |

Avant 12x24x6 Bearing (1) |

$ 4.99 |

| AV950540 |

Avant Mostro Main Blade Grip Bearing Spacer 16×1.0mm |

$ 8.99 |

| AV950541 |

Avant Tail Blade Grip Bearing Spacer 8×0.3mm |

$ 5.99 |

| AV950550 |

Avant M4x24mm Socket Head Cap Shouldered Screw and M4 Locknut |

$ 4.99 |

| AV950551 |

AV950551 Avant M4x18mm Socket Head Cap Shouldered Screw and M4 Locknut for 17T Pinion |

$ 4.99 |

| AV950552 |

AV950552 Avant Mostro Main blade Grips M5 Screws and locknuts |

$ 11.99 |

| AV950800 |

Avant Zero degree Alignment tool for Mostro 700 Bladegrips |

$ 14.99 |

| AV950850 |

Avant Mounting and connection kit for Kontronik Kosmik ESC |

$ 28.99 |

| AV960400 |

Avant Mostro Nitro Carbon Side Frame |

$ 99.98 |

| AV960401 |

Avant Mostro Nitro Bottom Plate |

$ 11.99 |

| AV960402 |

Avant Mostro Nitro Middle Stiffener Plate |

$ 11.99 |

| AV960403 |

Avant Mostro Nitro Top Stiffener Plate |

$ 11.99 |

| AV960404 |

Avant Mostro Nitro Battery Plate |

$ 22.95 |

| AV960405 |

Avant Mostro Nitro Side Frame Stiffener Plate |

$ 11.99 |

| AV960406 |

Avant Mostro Nitro Motor Bolts Plate (2) |

$ 11.99 |

| AV960409 |

Avant Mostro Nitro Hollow Main Shaft |

$ 21.99 |

| AV960410 |

Avant Mostro Nitro Clutch |

$ 27.99 |

| AV960411 |

Avant Mostro Nitro Clutch Bell |

$ 22.99 |

| AV960412 |

Avant Mostro Nitro Clutch Bell Liner |

$ 6.99 |

| AV960413 |

Avant Mostro Nitro Clutch Stack Hollow Threaded Shaft |

$ 9.99 |

| AV960414 |

Avant Mostro Nitro 24T Engine Pulley |

$ 16.99 |

| AV960415 |

Avant Mostro Nitro 25T Engine Pulley |

$ 16.99 |

| AV960416 |

Avant Mostro Nitro 26T Engine Pulley (Kit Default ) |

$ 16.99 |

| AV960417 |

Avant Mostro Nitro Clutch Stack Nut |

$ 8.99 |

| AV960418 |

Avant Mostro Nitro Starter Shaft Bearing Block |

$ 15.99 |

| AV960419 |

Avant Mostro Nitro Clutch Stack Sliding Plate |

$ 38.99 |

| AV960420 |

Avant Mostro Nitro Aluminum Landing Skids |

$ 14.99 |

| AV960421 |

Avant Mostro Nitro Aluminum Landing Skids |

$ 14.99 |

| AV960430 |

Avant Mostro Fuel Tank Assembly |

$ 22.99 |

| AV960431 |

Avant Mostro Nitro Fuel Tank Hardware |

$ 16.99 |

| AV960432 |

Avant Mostro Fuel Tank Rubber Strip |

$ 12.99 |

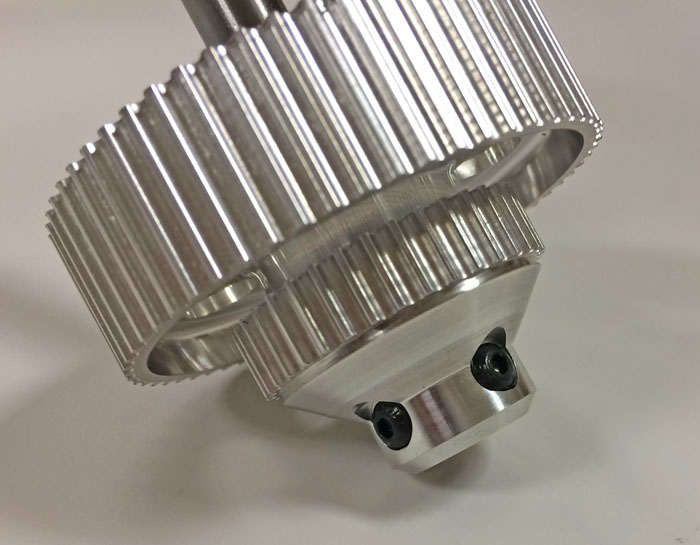

| AV960440 |

Avant Mostro Aluminum CNC Machined Fan |

$ 44.99 |

| AV960441 |

Avant Mostro Nitro Motor Mounts |

$ 35.99 |

|

|

|

| Mostro/Aurora common Parts |

|

| AV000110 |

Avant CCPM Anti-rotation guide Pin |

$ 5.99 |

| AV000121 |

Avant Hex Starter Adapter |

$ 12.99 |

| AV000123 |

Avant Steel balls M2 (5) |

$ 8.99 |

| AV000124 |

Avant Steel balls M3 (5) |

$ 9.99 |

| AV000126 |

Avant Standard Ball Link (10) |

$ 9.99 |

| AV000127 |

Avant Ball Link Thick Thread (4) |

$ 4.99 |

| AV000128 |

Avant Canopy grommets |

$ 5.99 |

| AV000133 |

Avant Tail Y-link |

$ 4.99 |

| AV000135 |

Avant Washout Y-Link |

$ 4.99 |

| AV000136 |

Avant 6mm Starter Shaft |

$ 9.99 |

| AV000138 |

Avant Black UV-rated Cable ties |

$ 4.99 |

| AV000140 |

Avant Mostro and Aurora Follower Arms with bearings, Y-Links and pins |

$ 24.99 |

| AV900214 |

Avant Aluminum Landing Skids |

$ 12.99 |

| AV900229 |

Avant Tail Slider threaded Brass Sleeve |

$ 7.99 |

| AV900242 |

Avant Tail Output Shaft |

$ 12.99 |

| AV900245 |

Avant Tail Hub |

$ 14.99 |

| AV910309 |

Avant Cooling Fan ( Kit Default ) |

$ 12.99 |

| AV910311 |

Avant Fan Shroud Set |

$ 17.99 |

| AV910314 |

Avant Fan Hub Threaded 5/16-24 (OS) |

$ 19.99 |